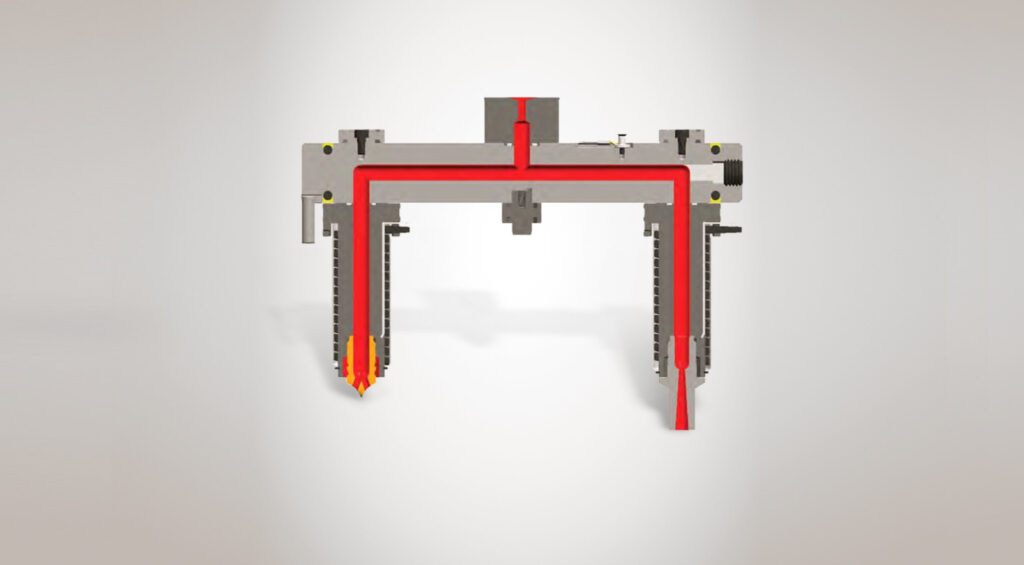

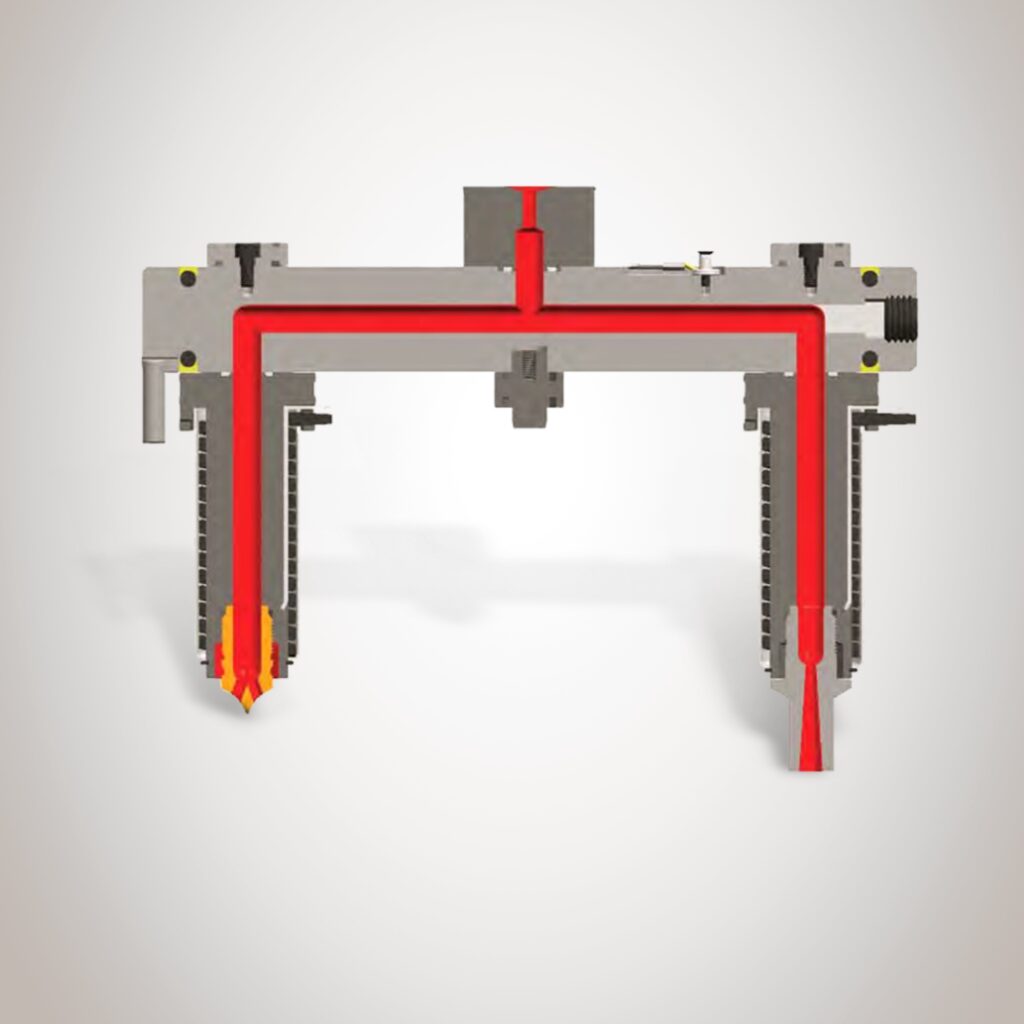

Open Gate System

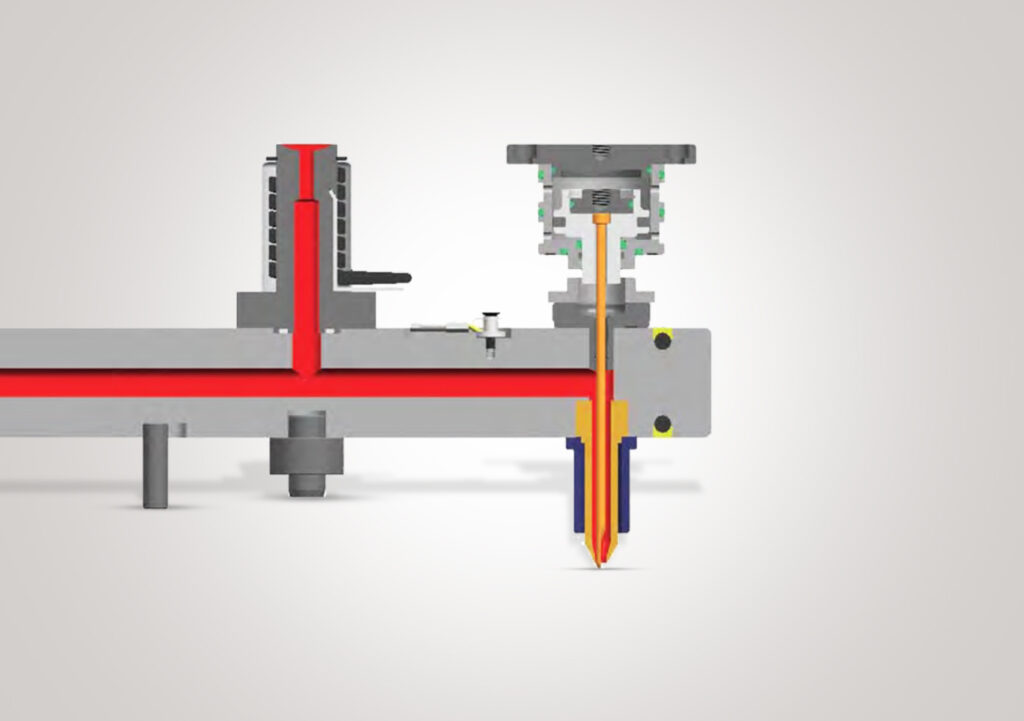

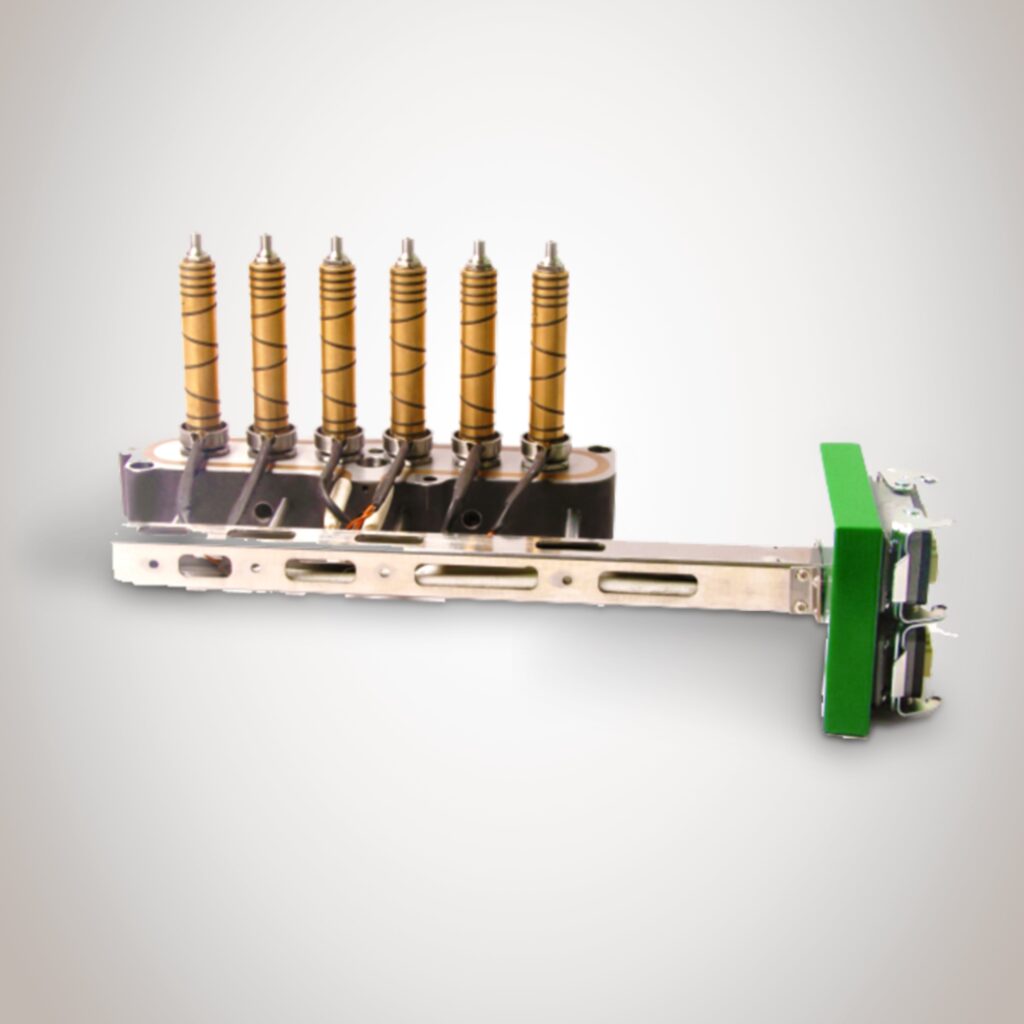

Open Gate Systems are most commonly used direct gating method either with pinpoint or sprue. Economical and proven high-quality system to process wide range of general and engineering plastic products ranging from small to big sizes.

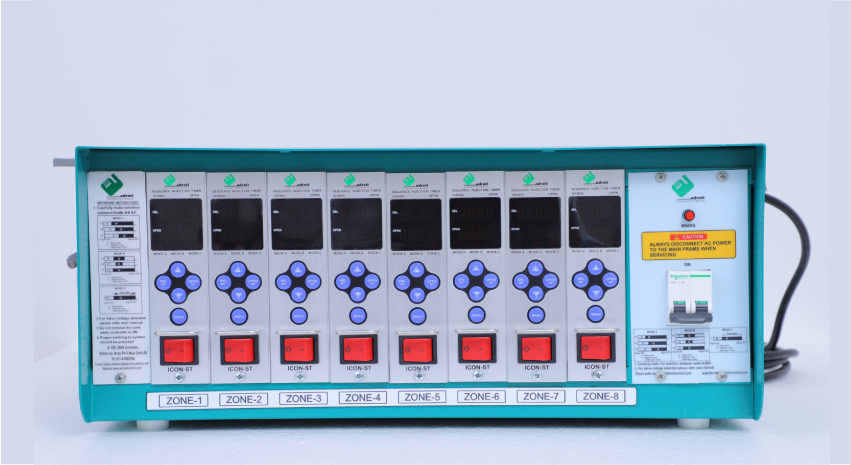

Features:

Cost effective and greater variety of standard products | Great for high cavitation moulds with close cavity pitch dimensions | Externally heated systems for outstanding processing results | Exchangeable tip, bush, thermo-couple and heating element